Lease Daily Entry

After a successful login by a pumper the program will start on the home page. It will display the default route. See Basic Navigation for more information on navigating this screen.

Once the pumper is selected the date will default to the last date processed for the pumper. When the program is started in the morning for the first time the date should be incremented. If a pumper has not been selected the date will default to the current calendar date. A new processing date can be entered using the calendar control or by using the Previous Date and Next Day links.

To enter the information for a lease for the day, click the lease name link on the Home page. The daily entry page will be displayed.

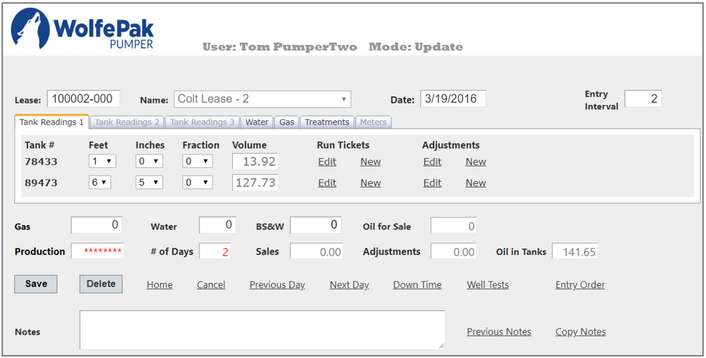

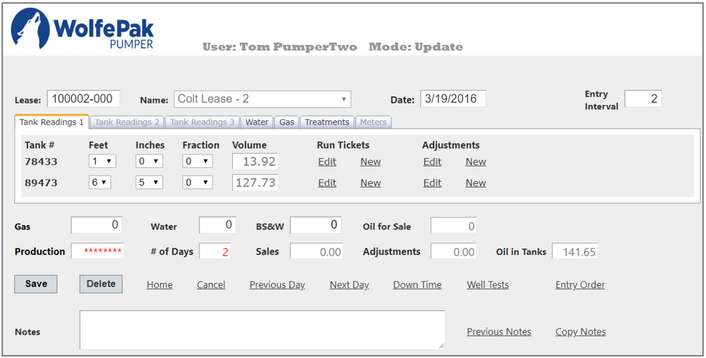

Allow up to 4 tanks. Each tab becomes enabled depending on the number of tanks on the lease.

Lease

|

Lease Number

|

Name

|

Lease Name

|

Date

|

Current Date

|

Entry Interval

|

Interval defined in Lease Maintenance. If setup to allow changing interval, the value will result in a new entry interval for the lease after current day information is saved. The field office should be consulted before changing the entry interval on a lease.

|

Tank Readings

Feet/Inches/ Fraction

|

Default to the values for the previous day, meaning the current tank volumes are displayed. When the readings are changed the volumes will be updated when the information is saved.

These are changed by using the drop down associated with the tank. The Volume field will auto calculate and cannot be manually adjusted.

|

Run Tickets

|

See Run Tickets for more information.

|

Adjustments

|

See Adjustments for more information.

|

Gas field

|

5 options to enter gas volumes:

1.A volume is entered. The volume is entered in the Gas field. To enter more information, such as tubing pressure, casing pressure, choke size, and strokes per minute, go to the Gas Tab. The entry of these values is optional.

2.The volume is calculated using static and differential pressures. The Gas field will be disabled. Enter information on the Gas Tab. The static and differential pressure must be entered unless the Hrs. on field is blank. If Hrs. on field is blanked, the lease will show zero gas production. The values for the tubing and casing PSI, the chock, and SPM can still be entered. All other values default to the previous day values.

3.The volume is calculated using a meter reading. A volume can still be entered in the Gas field. If values are entered on the Gas Tab they will override any value entered in the Gas field. If today’s reading is entered in the Reading field, the program will calculate the MCF produced. If the meter is asleep, gets reset or is not accurate for some other reason an estimated production can be entered in the MCF filed on the Gas Tab.

4.The volume is calculated using gas as a production meter and has injection and buy back meters.

5.The lease does not produce gas. The Gas field will be disabled. |

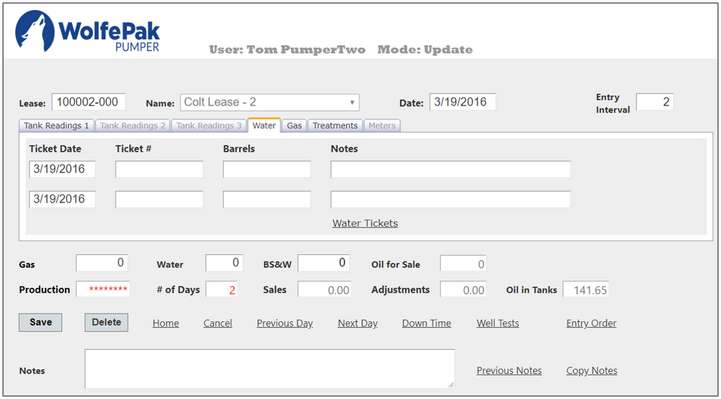

Water field

|

There are 4 options for water production.

1.Water volume is entered and not calculated by the program.

2.Water tank volumes combined with water haul tickets.

3.Water tank volumes combined with meter readings.

4.Meter Readings

If the water value is entered for the lease any water hauled from the lease can be entered by selected the Water Tab. These entries will not affect the water production recorded for the lease. The entered value will be used.

|

BS&W

|

Enter the total BS&W in all tanks. The BS&W value will change the production amount by comparing today’s BS&W with the value from the previous day. If the BS&W for today is less than the previous day, it will increase production.

|

Oil for Sale

|

Oil in Tanks less the BW&W volume.

|

Production

|

If Production Entry is missing, the Production and # of Days fields will show red. The values on this row and the Oil for Sale are calculated by the program and will be updated when the day’s readings are entered and saved.

|

# of Days

|

The number of days covered by the entry. 1 if entered daily, can be 2 if entered every other day.

|

Sales

|

Any oil sales entered either as a run ticket or a LACT sale.

|

Adjustments

|

Any oil adjustment volumes entered for the day.

|

Oil in Tanks

|

The total oil volume in all the tanks.

|

Also see Down Time and Well Tests.

|

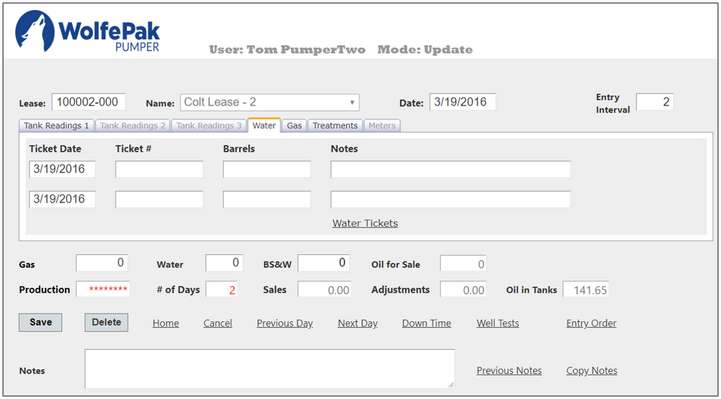

If Water value is entered, any water hauled can be entered here. These entries do not affect the water production recorded for the lease. The entered value will be used.

Ticket Date, Ticket Number, Barrels, and Notes.

|

Data Entry fields

|

Water Tickets link

|

Used to enter more than two Water Tickets for that day or to view all water tickets.

If Water value is calculated using tank volumes and water haul tickets, there will be Water Tanks. Works the same as Oil Tank entry tabs.

Water Hauls – Used for water hauled from the lease. See Water Hauls.

•Adjustments – Used for making adjustments. See Adjustments.

If Water Volume is calculate using meters and tanks, there will be Water Tanks. Works the same as Water calculated using tank volumes and water haul tickets, EXCEPT for lease disposal meters are used to enter disposal volumes instead of water hauls.

If Water is Calculated using only meter volume, the water tab is not used to record tank volumes. Although a dummy tank can be setup to allow entry of adjustments.

|

Save

|

When the information is saved the production is calculated and placed in the water field. The tank volume is updated. If water is hauled from the lease the Water Hauls links are used.

|

|

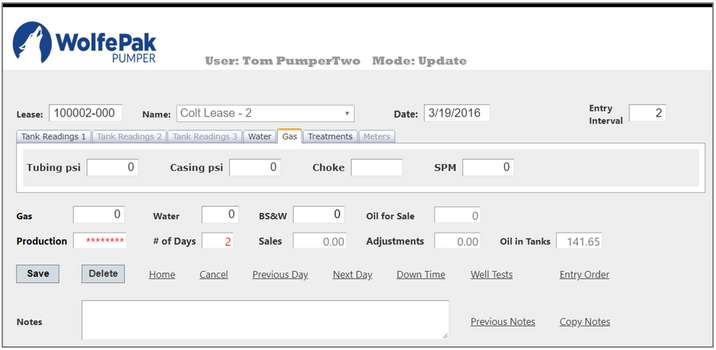

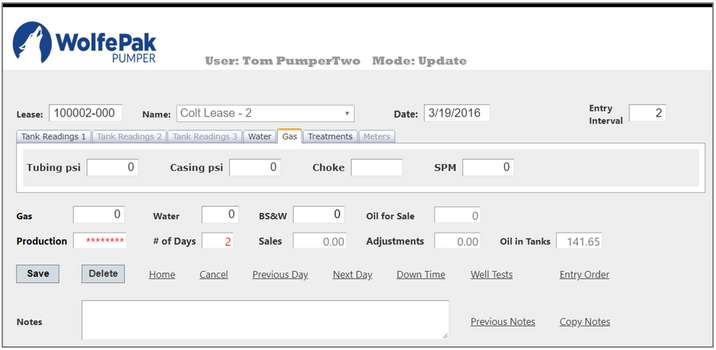

This tab will look differently depending on how it is setup and how the Gas is being entered.

Tubing psi

Casing psi

Choke

SPM

|

The entry of these values are optional. If the gas is an entered value or the lease does not produce gas these are the only values that can be entered. These values will default to the values for the previous day.

|

|

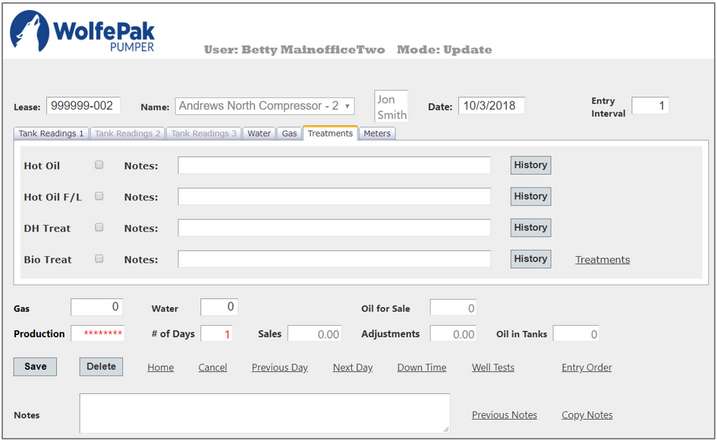

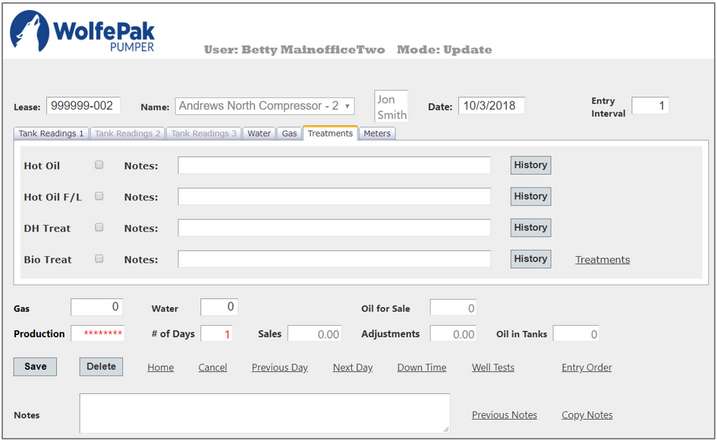

Edit

|

Make changes to an existing Treatment

|

New

|

Enter the following information:

Well – Select a well. The field can be left as “-Select Well-”. In this case the treatment will go against the lease rather than a specific well.

Treatment Date – The value is required and cannot be in the future. Defaults to the current processing date.

Treatment Type – Select the treatment type from the drop down. A value must be selected.

Notes – Enter any optional notes about the treatment.

|

|

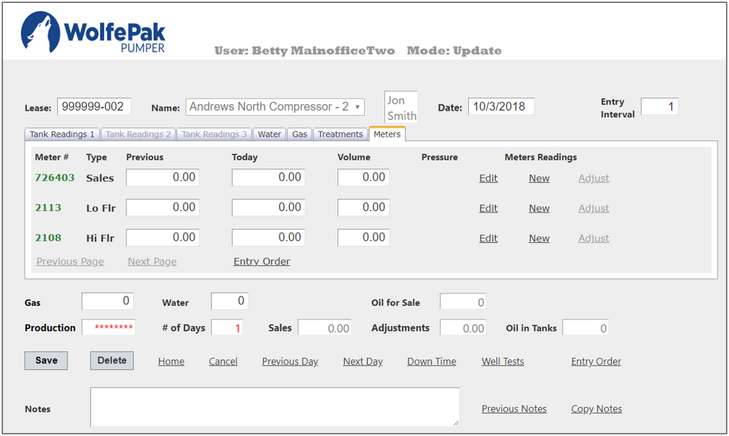

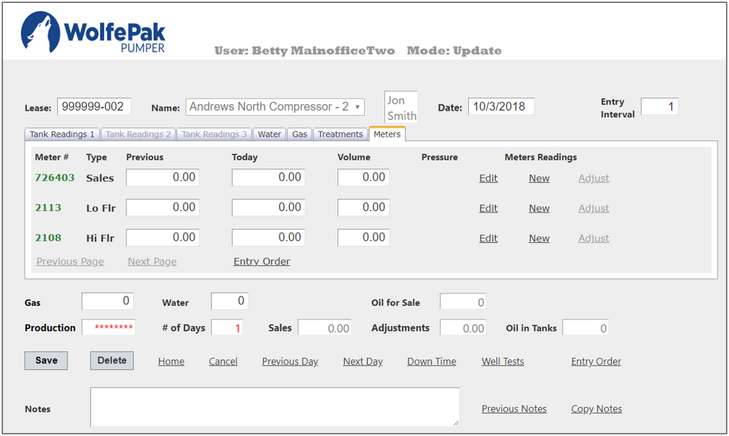

It is important to know that the production for the day of the reading may be recalculated depending on the meter type and this could result in negative or out of tolerance production.

Edit

|

Make changes to an existing Meter Reading

|

New

|

Enter the following information:

Reading Date – It cannot be in the future. Defaults to the current processing date.

Previous Reading – This will default to the last reading for the meter. It can be changed if required.

Today’s Reading – Enter the reading for today. It must be greater than the Previous Reading or zero. If the value is zero the Volume value will be used.

|

|