This report is provided in CSV format. Printing or Viewing the report will create a file in the GLN32\00000\EDI\MMSOGOR.CSV

See Folder Transfer/Compare regarding moving files between WPA and your local folder.

Minerals & Management Services

Oil and Gas Operations Report (OGOR) Form ONRR-4054

The OGOR is a summary of all operations conducted on a lease/agreement during a specific production month. This report is typically filed monthly by each operator of an offshore OCS, onshore, or Indian lease/agreement that contains active wells. It is due by the 15th of the second month following the production month for manual submissions and by the 25th of the second month following production if filing electronically. It consists of three parts:

Part A accounts for all production and injection data on a lease agreement by well and producing interval, including the well status.

Part B accounts for the total disposition of lease/agreement production for each product and may include direct sales, transfers and lease/agreement use.

Part C accounts for production and sales attributable to a lease/agreement produced into inventory before the production is sold from a storage facility. It identifies beginning inventory, ending inventory, production, sales and adjustments.

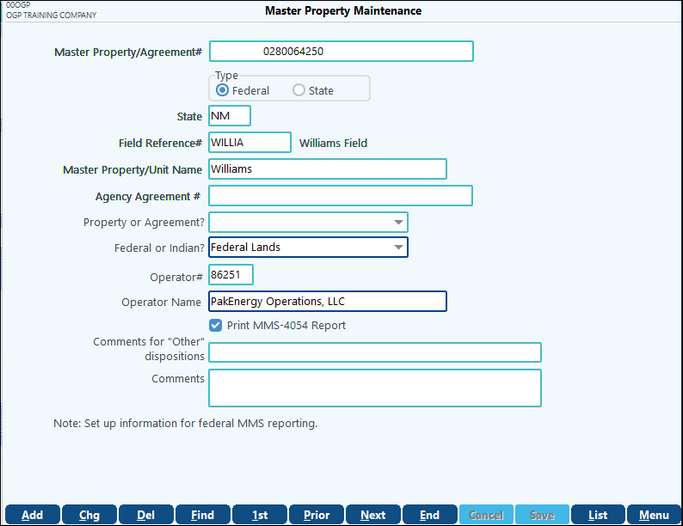

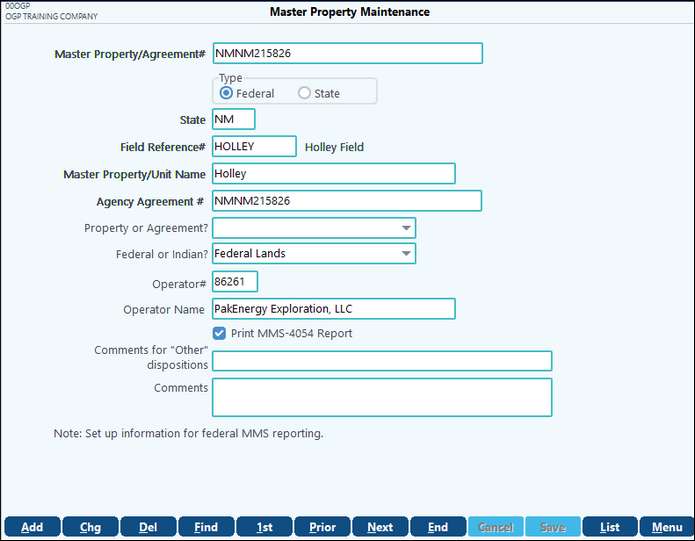

Pak Accounting has the capability to create this report for an operator when the necessary setup is complete. First, the Lease/Agreement information must be set up in OGP module - Master File Maintenance - Master Property.

Below are 2 examples.

•In Figure 1, the Agency Agreement # is blank.

If the Agency Agreement # is blank, the report will use the agreement # in the Master Property/Agreement # as the MMS Lease/Agreement Number.

•In Figure 2, the Agency Agreement # is the same as the Master Property/Agreement #.

If there is an agreement # in the Agency Agreement # field, the report will use that number as the Agency Agreement Number.

If any of the leases in this agreement are Indian lands, the Federal or Indian field must be set to Indian. This will ensure that the Indian flag will be set on the OGOR Part A.

Figure 1

Figure 2

The next critical setup is the Property Maintenance > ONRR Options tab.

•The Agreement Number from the Master Property Maintenance is entered in the Agreement Number field. This must match the number set up on the Master Property Maintenance. Use the lookup to ensure you select the correct one for this property.

•The API Well Number is the same API number as on the Other tab of the Property Maintenance.

•Enter the Producing Interval code for this well from the Minerals Production Reporters Handbook Appendix G.

•Enter the Well Status for this well from the Minerals Production Reporters Handbook Appendix H.

•If this well produces gas, enter the MMS-assigned metering point number in the Gas Plant Number field.

See the Minerals Production Reporter Handbook for more information

(Paper Reports) OGOR Part A Header Information

Pak Accounting report containing information to complete the paper form. Numbers correspond to field numbers on the paper form.

1. Reporter use |

Reserved for your use. |

2. Indian |

This box will be flagged if the option on the Master Property Maintenance for Federal or Indian is set to Indian. |

3. ONRR Use |

Reserved for ONRR use. |

4. Report Type |

Pak Accounting only creates the original report. Reports for corrections must be prepared manually. |

5. ONRR Lease/Agreement Number |

Pulls from the Agreement Number on the MMS Options tab of Property Maintenance. This is assigned to the property after the Master Property has been set up. There may be multiple wells/properties with the same Agreement Number. |

6. Production Month |

Is keyed in when running the report. Cycle for the month must be at least started or has been updated. |

7. ONRR Operator # |

Pulls from the Operator # entered on the Master Property Maintenance. |

8. Operator Name |

Pulls from the name entered on the Master Property Maintenance. |

9. Operator Lease/Agreement Name |

Pulls from the Master Property/Unit Name entered on the Master property Maintenance. |

10. Operator Lease/Agreement # |

This is the property Sub-Account for your well/property. |

OGOR-A Detail Information

11. Line Number |

This is preprinted on the paper report form. |

12. Action Code |

Use A (add) to enter new information on an Original report, to add new or revised detail lines on a Modify report, or to add replacement lines on a Replace document for previously submitted reports. Use D (delete) on a Modify report to remove a detail line entered on a previously submitted report. The Delete line must match the previously accepted Add line. If you use a D, you must check Modify in field 4. |

13. API Number |

The API Number entered on the MMS Options of Property Maintenance. |

14. Producing Interval |

The Producing Interval on the MMS Options of Property Maintenance. |

15. Operator Well Number |

The Sub-account code from Property Maintenance for the property being reported. |

16. Well Status Code |

The Well Status Code on the MMS Options of Property Maintenance. |

17. Days Produced |

The number of days the well was producing during the month. |

18 Oil/Condensate (bbl) |

Total production of oil/condensate entered in whole barrels by API well number producing interval. Volumes pull from Summary Maintenance. |

19. Gas (mcf) |

The net volume of all formation gas excluding lift gas by API well number producing interval. Volumes pull from Summary Maintenance. |

20. Water (bbl) |

The production volume of water in barrels by API well number producing interval. Volumes pull from Summary Maintenance. |

21. Injection Volume |

The volume of oil, gas, or water injected into the well. Pulls from the Injection section of Summary Maintenance |

22. Total Production |

The total oil, gas, and water based on the detail volumes entered. |

23. Total Injection |

The value of this field is based on the detail volumes and well status entered. |

The Authorization section is required only on the first page of a multi-page/multi-part paper report.

OGOR-B Production Disposition

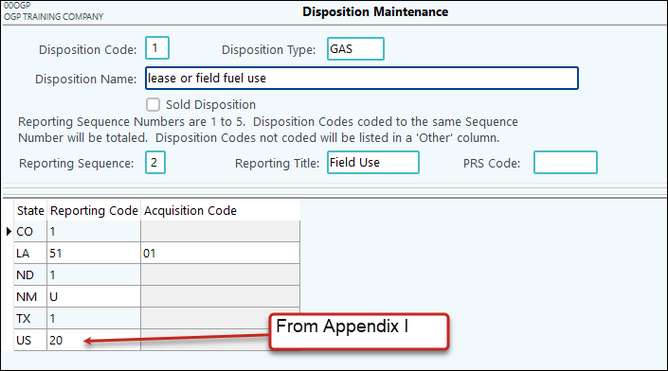

This section describes the disposition activity for all products produced for the reporting entity for this reporting period. The disposition codes must be set up in Company Maintenance under Disposition maintenance for each product for each type of disposition from the Minerals Production Reporters Handbook Appendix I. For example: Your internal disposition code for lease use gas is 1 but the US code for lease use gas is 20.

31. Line Number |

This line is preprinted on the paper report form. |

32. Action Code |

Use A (add) to enter new information on an Original report, to add new or revised detail lines on a Modify report, or to add replacement lines on a Replace document for previously submitted reports. Use D (delete) on a Modify report to remove a detail line entered on a previously submitted report. The Delete line must match the previously accepted Add line. If you use a D, you must check Modify in field 4. |

33. Disposition Code |

Enter the code that identifies the disposition of the product. Each product must be on a different line. A disposition code can be used more than once if the metering point or gas plant number is different. |

34. Metering Point Number |

Offshore – Enter the BSEE-assigned metering point number aka Facility/Measurement Point Number (FMP) for those disposition codes requiring it. See Appendix I. Onshore – enter one of the following: The BLM-assigned FMP number, or The actual serial number inscribed on the equipment, or The internal tracking number for the meter/facility, or Leave it blank. (Note: the ONRR recommends entering the FMP number for disposition codes 01, 05, 06, 07, 09, 11, 12, or 16. |

35. Gas Plant Number |

Enter the ONRR or BSEE assigned metering point (FMP type 02) that identifies the gas plant where the gas is processed before royalty determination (disposition code 11 or 12). Pulls from the MMS Options tab of Property Maintenance. |

36. API Gravity |

Enter the API gravity of oil/condensate with one decimal point at standard conditions specified in the BLM or BSEE regulations. Pulls from Summary Maintenance. |

37. BTU |

Enter the Btu quality of gas sold or transferred to a facility as a whole number at standard conditions specified in the BLM or BSEE regulations. Pulls from the Monthly Gas Sales. |

38. Disposition Volumes (bbl/mcf) |

Enter the volume in the appropriate column for the product disposed. For oil/condensate, enter barrels corrected for temperature, basic sediment and water (BS&W) according to the standard conditions specified in the BLM or BSEE regulations. For gas enter the Mcf corrected for temperature and pressure base according to the standard conditions specified in the BLM or BSEE regulations. For water, enter whole barrels. Pulls from Summary Maintenance. |

39. Total Dispositions (Oil/Gas/Water) |

Total calculated from the detail volumes entered. |

OGOR-C Inventory Activity

This section describes the inventory activity for all oil/condensate and CO2 production for the reporting entity.

40. Line Number |

This line is preprinted on the paper report form. |

41. Action Code |

Use A (add) to enter new information on an Original report, to add new or revised detail lines on a Modify report, or to add replacement lines on a Replace document for previously submitted reports. Use D (delete) on a Modify report to remove a detail line entered on a previously submitted report. The Delete line must match the previously accepted Add line. If you use a D, you must check Modify in field 4. |

42. Product Code |

Enter the code identifying the specific product – oil (01), condensate (02), or CO2 (17) being stored – for the Inventory Storage Point Number. |

43. Inventory Storage Point Number |

This field identifies the tank or other equipment used for inventory storage. For offshore, enter the BSEE-assigned FMP # identifying the inventory storage facility (FMP type code 01 or 05) at which the oil/condensate is stored prior to sale. For onshore, enter the BLM-assigned FMP number, OR the actual serial number inscribed on the equipment, OR the internal tracking number for the meter/facility, OR leave it blank. |

44. Metering Point Number |

Complete this field only if the royalty volume of oil/condensate is metered and sold at a point downstream of the inventory storage point number. For offshore- enter the BSEE-approved meter (FMP) that measures the volume of production subject to royalty. For onshore – enter the BLM-assigned FMP number, OR the actual serial number inscribed on the equipment, OR the internal tracking number for the meter/facility, OR leave it blank. |

45. API Gravity |

The API gravity of oil/condensate entered with one decimal at standard conditions. Pulls from Avg API Gravity on Summary Maintenance. |

46. Beginning Inventory |

The volume in barrels of oil/condensate or Mcf for CO2 that exists in the facility at the beginning of the production month (must match ending inventory for the previous production month). Pulls from BOM in Summary Maintenance. |

47. Production |

The volume in barrels for oil/condensate or Mcf for CO2 produced into the facility during the production month. Pulls from Production in Summary Maintenance. |

48. Sales |

The volume in barrels for oil/condensate or Mcf for CO2 sold from the facility during the production month. Pulls from Sales in Summary Maintenance. |

49. Adjustment Code |

The code identifying the reason for inventory adjustments showing in field 50. Pulls from the Dispositions section of Summary Maintenance. |

50. Adjustment Volume |

The volume in barrels of oil/condensate or Mcf for CO2 of adjustments to inventory. |

51. Ending Inventory |

The volume in barrels of oil/condensate or Mcf for CO2 in the facility at the end of the production month. Pulls from Summary Maintenance. |

52. Totals |

Totals for each column. |