What on the surface appears to be a tremendous amount of information can be entered into the system in a matter of seconds! Rather than entering each reading, the system accepts the increment breakdown from the top of each tank chart, and calculates volume on the fly.

NOTE: Before you set up Tank/Meters, you must set up each facility you plan to use in the system; this includes all leases and stations. The three tabs in Property Maintenance to focus on are the General, Production, and Company Opts Tabs. NOTE: You will only see the Production tab while in the First Purchaser Module.

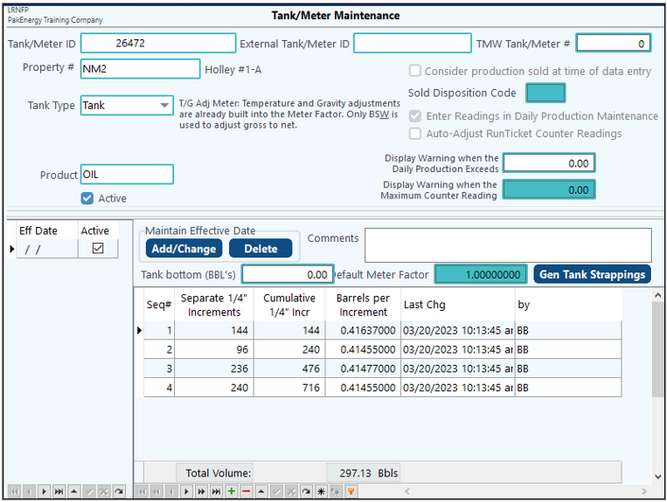

Tank/Meter Maintenance |

|

|---|---|

Tank/Meter ID |

Tank #/Meter ID or Lact #. |

External Tank/Meter ID |

Used with various Run Ticket imports - allows you to use a different tank/meter number than yours. Also see Code Run Ticket import. |

Property |

Property where the tank is located. Select property entered in the Property Master. |

Tank Type |

There are two types of tank types: Tank and Non-Tank (Meter, LACT, and T/G Adj Meter). •Tank: the strappings are defined and determine the volume that is in the tank for each 1/4 inch increment.The starting and ending gauge reading are entered when this type of tank is used in regards to the run ticket. •Non-Tank: Meter or LACT unit - a starting and ending reading number are entered, along with the average line temperature. (There are no functional differences between a Meter and a LACT). The gross volume is determined by the difference in the two readings. •T/G Adj Meter – is a special type of meter that has the temperature and Gravity adjustments already built into the Meter Factor. Only BS&W will be used to adjust gross to net. •Add-On: Tank Import: Strapping utility to convert Tank Strapping measurements into tank strappings. |

Product |

Select which product this Tank/Meter contains: Oil or Condensate. |

Active |

Ability to deactivate Tanks, Meters and LACT Units. (NOTE: option will be checked "active" by default.) |

Consider production sold at time of data entry |

This field is not currently being used by First Purchaser. (Used by Production) |

Sold Disposition Code |

This field is not currently being used by First Purchaser. (Used by Production) |

Enter readings in Daily Production Maintenance |

This field is not currently being used by First Purchaser. (Used by Production) |

Auto-Adjust Run Ticket Counter Readings |

If checked, when entering RunTickets for a LACT Unit, the system will automatically adjust and recalculate Net Volume for the corresponding prior RunTicket's Ending Counter Reading based on the current RunTicket's Starting Counter reading. If a corresponding subsequent RunTicket exists, the system will also adjust its Starting Counter reading based on the current RunTicket's Ending Counter reading. |

Display Warning when the Daily Production Exceeds |

This field is not currently being used by First Purchaser. (Used by Production) |

Display Warning/Maximum Counter Reading |

This is used on LACT unit tickets to populate a warning when entering readings if it is over this value. |

Effective Date/Active |

Allows the user to have multiple tank strappings /meter factors. Also allows the user to keep historical records. |

Default Meter Factor |

Set default factor to be used. This will be the default on the Run Ticket. This can be changed during data entry. |

Tank Bottom |

The measurement of the sediment at the bottom of the tank in BBL increments. |

Strappings |

Measurement of the oil volume defined in increments to compute total tank capacity. Negative numbers are not allowed. Must be in 1/4 inch increments. |

Comments |

Add comments as needed. |

Maintain Effective Date |

Options to: •Add Copy from Previous •Add New Set •Change Effective Date •Delete Effective Date |

NOTES:

•Backgauge is a term that refers to oil that is picked up from an unstrapped or uncalibrated meter. The calibrated offload measurements are used to report and pay for the oil.

•When calculating a ticket that is set to a backgauge tank, the pickup meter readings are based on the offload volume. To accomplish this, set up a global tank @BACKGAUGE as a meter tank. When saved, the pickup meter readings will be set to start at zero and end at the gross volume from the offload.

•Pak Accounting now allows meter tickets to apply to a "Correction Meter Factor" (seen if the ticekt is designated as "Meter") on the ticket. With this change you are now able to enter in the Starting and/or Closing reading. Tank strappings are now date sensitive.

List

•This will take you to Reports/Property tab. Run the YT-1 Tank/Meter Listings or YT-2 Tank Strapping Report.

•If the "external Tank ID option is selected on the Tank Meter Listing, the listing will be a simple listing.

Utilities

Copy Tank/Meter ID - This utility allows multiple tanks/meters to be copied/moved at one time.

Change Tank/Meter ID - This utility allows for a tank/meter to be changed to a new Tank ID. Ticket history will be changed to correspond to the new Tank ID. The change can occur for one TankID at a time or changes can be imported from a CSV file. The file format should be in the following sequence: Property#-Column 1, OldTankID-Column2, NewTankID-Column3.

Import Tank/Meter - Tanks and Meters may be imported using the "Import Tank/Meter" import located by clicking on the Utilities button at the bottom of the screen. Negative numbers are not allowed for bbl's or increments.The import also features and undo option that will require an import stamp. If used, the "Undo" will delete the Strappings from the Tank Master, Tank Detail, and Tank Strappings table. NOTE: This import will only allow one of the two to be imported: TotalInches or TotalInches4. This import will also enable you to import strapping tables directly.

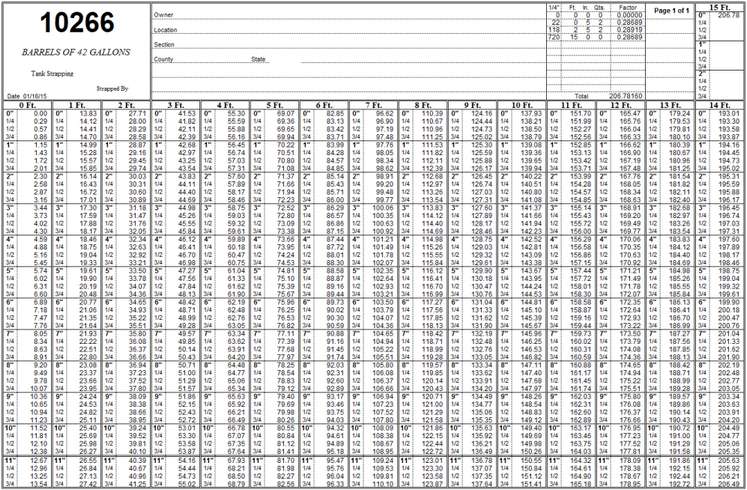

The "Scan Strapping Dir" button will look through the strapping folder for XLSX files to import. It will read in the the custom Tank table information, Tank# in cell B2, 1/4" increments in cells X2-X13, and Factor in cells AA2 thru AA13. The Tank# should be unique within the system and already exist. See the example below:

NOTES:

•Pak Accounting now allows meter tickets to apply a “Correction Meter Factor” (seen if the ticket is designated as “Meter”) on the ticket. With this change you are now able to enter in the Starting and/or Closing reading. Tank strappings are now date sensitive.

•The List button at the bottom of the screen will provide the Tank Meter Listing or Tank Strapping Report for a specified effective date. If the "External Tank ID option is selected on the Tank Meter Listing, the listing will be a simple listing.

•The External Tank/Meter ID and External Tank/Meter # can now be cleared if the TMW Cross Reference entry no longer exists for the associated property.